Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

Hydraulic Metal Sheet Shearing/Cutting Machine for Solar buffer water tank production line

The hydraulic shearing machine features an integral welded frame that has undergone vibration failure treatment, as well as hydraulic transmission and nitrogen return. It is equipped with a fence-type electrical interlocking safety protection device, cutting edge gap adjustment signs for quick and easy adjustments, a digital display device for the back gauge size and number of cuts, and a light alignment device to facilitate marking and cutting.

Pneumatic Metal Sheet Shearing/Cutting Machine for Solar buffer water tank production line

The pneumatic shearing machine boasts a simplistic structure, effortless operation, and eliminates the need for foot pedals or motor drives. It saves time and effort while maintaining low processing costs. This machine is primarily utilized for sheet shearing in solar water heater and water tower facilities with an effective working length of up to 3000mm and capable of cutting through plates ranging from 0.1-1.2M thick. Its dimensions are 3.5m x 0.8m x 1.3m.

Solar Geyser Production Line - Hydraulic Metal Plate Sheet Cutting / Shearing Machine

The mechanical shearing machine features a compact and simplistic structure, incorporating a clutch mechanism consisting of resistance keys and open gear transmission. It also utilizes advanced electrical components to ensure low operational noise, easy maintenance, aesthetically pleasing design, safety and reliability. This machine is primarily designed for cutting various types of plates with an effective working length of 3000mm, power output of 4KW and capable of shearing plate thicknesses ranging from 0.1-12MM. Machine dimensions are measured at 3m x.

Deep Throat Punch for Solar buffer water tank production line

The deep throat punch is constructed from pig iron and features both electrical and mechanical operating mechanisms. With a mouth depth ranging from 350-1500MM, the machine measures 0.8m x 1.5m x 1.8m in size.

Double head CNC punch for Solar buffer water tank production line

The double-head CNC punching machine is mainly used in the punching of solar water heaters. The inner tank is punched and flanged at one time. It can also be used to punch the outer tank of one head and the inner tank of the other head. The punching precision is of a high standard, with fast operating speeds and simple controls that minimize labor damage during the process. The worktable measures 2500mm in length, while the machine itself has a specification of 25T and dimensions of 3.5m x 2m x 1.8m.

One feeder, two single-head CNC punches for Solar buffer water tank production line

The belt and two CNC punching machines are primarily utilized for the punching operations of solar energy inner and outer gallbladders. With double-head punching capabilities, both inner and outer bladders can be punched simultaneously. The worktable measures 2500mm in length, with a specification of 16T, while the machine itself is sized at 3.5m x 2m x 1.8m

Ordinary punch for Solar buffer water tank production line

Ordinary punching machines are equipped with both electrical and mechanical operating mechanisms, enabling them to perform a variety of sheet metal processing tasks such as punching, flanging, stretching, and forming. The machine boasts a simple structure that allows for flexible operation and convenient maintenance. Additionally, an automatic feeding structure can be configured to further enhance its capabilities. This equipment is commonly used in the production of water heaters, security doors, and other similar products. Its dimensions measure 0.8m x 1.1m x 1.8m while its power output is rated at 1.5KW.

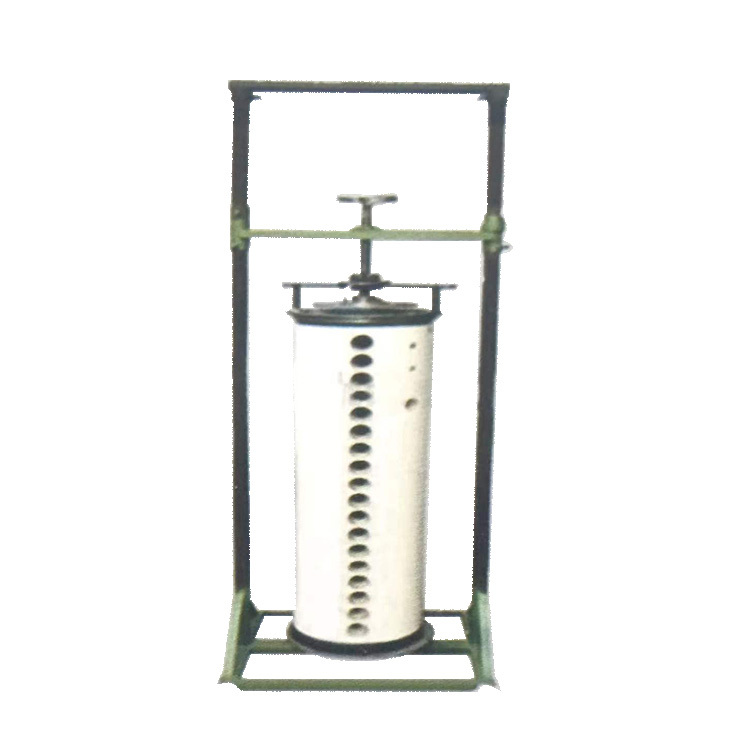

Single station Foaming Machine Solar Water Heater Foaming Line

The independent foaming frame securely fixes the inner and outer barrels, preventing eccentricity and shifting. This allows for one-time polyurethane foam injection, achieving overall foaming effects. Multiple independent foaming racks can be used in series to enable multi-station simultaneous foaming and improve efficiency

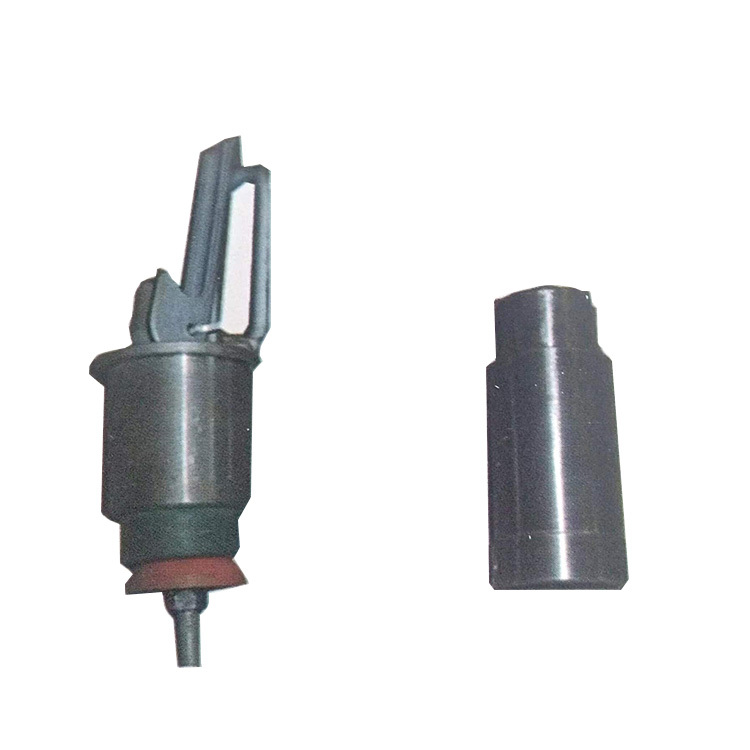

The foam plug is utilized to seal the mouth of the vacuum heat collector during the production of insulation layer for female Yang energy water heater, ensuring air tightness and integrity of foam, thereby enhancing insulation effect. It can be classified into ordinary foam plugs and positioning foam plugs.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,