Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

Double head CNC punch Solar Water Heater Vacuum Tube Holes Punching Machine

The double-head CNC punching machine is mainly used in the punching of solar water heaters. The inner tank is punched and flanged at one time. It can also be used to punch the outer tank of one head and the inner tank of the other head. The punching quality is high, the speed is fast, the operation is simple, and the damage to the labor in the punching process is reduced. The length of the worktable is 2500mm, the specification is 25T, and the size of the machine is 3.5m x 2m x 1.8m.

CNC Turret Punching Machine for Electric water heater

The CNC turret punch press (special) is custom-manufactured to meet the specific requirements of customers and is utilized in the sheet punching and drawing processes for specialized industries. It can be equipped with various special molds and turret designs tailored to customer specifications, including fan-shaped or disc-shaped turrets that operate at high speeds with exceptional precision. The worktable length is unrestricted, while the machine's specification ranges from 4-16 stations.

Upper and lower double cylinder Deep drawing hydraulic press for electric water heater cover

This machine is suitable for cold and hot pressing and forming of end covers for various vessels, as well as pressing, folding, and leveling of different steel plates. It adopts a cartridge valve integrated system that ensures reliability with long service life and minimal hydraulic pressing, thereby reducing the connecting line and leakage. The centralized buttons control allows adjustable working pressure and stroke within the prescribed range by selecting an operation panel.

Ordinary punch for Solar Water Heater Tank Production Line

Ordinary punches are equipped with both electrical and mechanical operating mechanisms, enabling them to perform a variety of sheet metal processing tasks such as punching, flanging, stretching, and forming. The machine boasts a simple structure that allows for flexible operation and convenient maintenance. Additionally, an automatic feeding structure can be configured to further enhance its capabilities. This equipment is commonly used in the production of water heaters, anti-theft doors, and other similar products. Its compact size measures 0.8m x 1.1m x 1.8m while requiring only 1.5KW of power.

Four-column three-beam double-cylinder Deep Drawing Press Machine

The three-beam and four-column structure is both economical and practical, featuring an integrated hydraulic control system with cartridge valves to minimize leakage points. This ensures reliable operation and a long service life. It supports two forming processes - fixed pressure and fixed stroke - that can be adjusted within the specified range via centralized button controls for manual, semi-automatic or automatic operations.

Deep Drawing Machine for Electric Water Heater Inner End Cap

The calibration hydraulic press is primarily utilized for the precise calibration and press-fitting of shafts and sleeves, as well as other similar technological applications. Its single-column upright structure ensures reliable performance.

Deep Throat Punch for Solar Water Heater Tank Production Line

The deep throat punch is constructed from cast iron and features both electrical and mechanical operating mechanisms. With a mouth depth ranging from 350-1500MM, the machine measures 0.8m x 1.5m x 1.8m in size.

Solar water heater Trimming and rolling machine

The edge trimming and crimping machine is primarily utilized for the processing of end caps, providing high-speed operation, superior quality output, and consistent flanging. It boasts an effective processing diameter range of 300-650mm, a power rating of 0.75KW, can handle plate thicknesses ranging from 0.2-1.2MM, and has dimensions measuring at 1.1m x 0.8m x 1.5m.

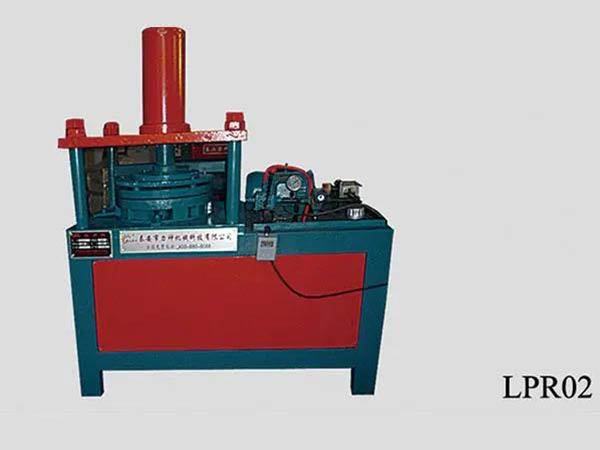

Small Deep drawing hydraulic press for electric water heater cover

The small press is mainly composed of a frame, four uprights, an oil cylinder, a hydraulic station, a fuel tank and other parts.The machine is primarily utilized for the production and processing of inner and outer bladder heads as well as barrel supports in solar energy applications. It features a compact design, low energy consumption, user-friendly operation, and high safety standards. With a tonnage range of 10-100 tons, power output of 7.5K, the ability to process sheet thicknesses ranging from 0.2-1.2M, and dimensions measuring at 2m x 1.1m x 1.7m.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,