Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

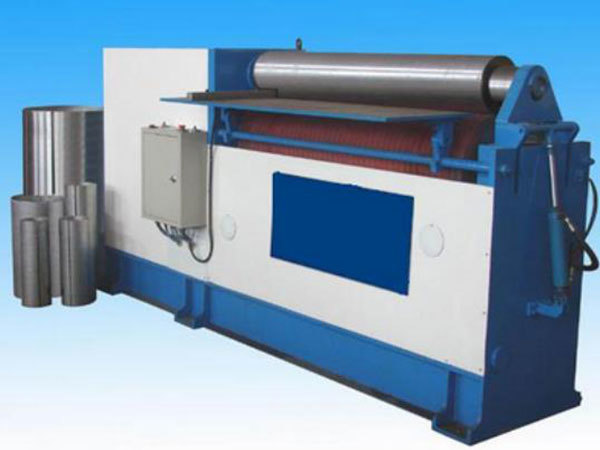

Three-roll plate rolling machine

The three-roll plate rolling machine is mechanically lifted and driven. It features a section steel welded frame that has undergone vibration aging treatment. The upper roller can be electrically lifted and separated, while various side wheels can be added to process different special-shaped structures according to customer requirements. With easy operation and high production efficiency, it can handle materials up to 4mm thick, with dimensions of 3.5m x 1m x 1.1m.

Double Roll Plate Rolling Machines

The double-roller plate rolling machine is mainly used for rolling cylindrical workpieces, which is fast in rolling, one-time forming, without leaving straight edges, and has high precision and high efficiency for rolling workpieces. One-key control, hydraulic pressing, simple operation and beautiful products. The working length is 2500mm, the power is 7.5KW, the thickness of the processing board is 0.2-6MM, and the machine size is 3.5 meters x 1.2 meters x 1.7 meters.

Three-roll symmetrical plate rolling machine

The plate rolling machine adopts a three-kun symmetrical structure, with the upper roller symmetrically positioned in the center of the two lower rollers for vertical lifting motion achieved through screw and nut transmission and worm drive. The two lower rollers rotate to provide torque for sheet rolling, meshing via gears. This machine tool boasts a compact design that is easy to operate and maintain, while also capable of pre-bending.

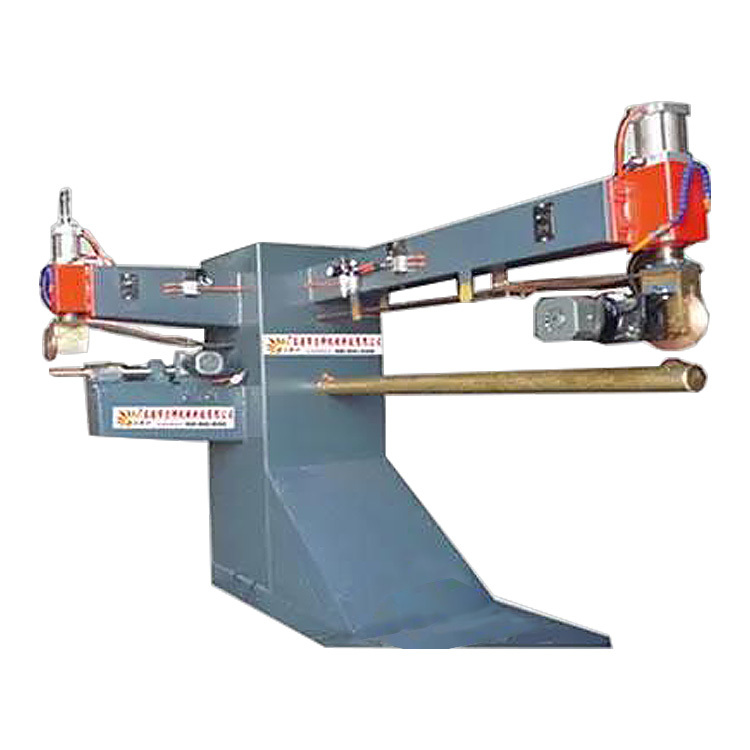

TIG Straight Seam Welding for Electric water heater production line

The TIG straight seam welding machine is capable of performing butt welding on various metal materials such as stainless steel, carbon steel, copper, titanium and aluminum without causing any deformation or intergranular corrosion to the workpiece. It can achieve single-sided welding and double-sided forming with excellent weld quality and high degree of automation, making it easy to operate. This machine is suitable for producing stainless steel products, electric water heaters, solar water heaters and other operations.

TIG Circumferential Welding Machinery for Electric water heater production line

The TIG girth welding machine utilizes a four-axis CNC welding system, with the main engine featuring linear motion in X, Y, and Z axes as well as rotational motion in R axis. This enables spatial linear or curvilinear movement of the welding process and adjustment of the angle between the torch and workpiece for completing various special-shaped welds. The equipment comprises a gantry-type welding torch bracket and a welding platform (with customizable self-made or pre-designed fixtures).

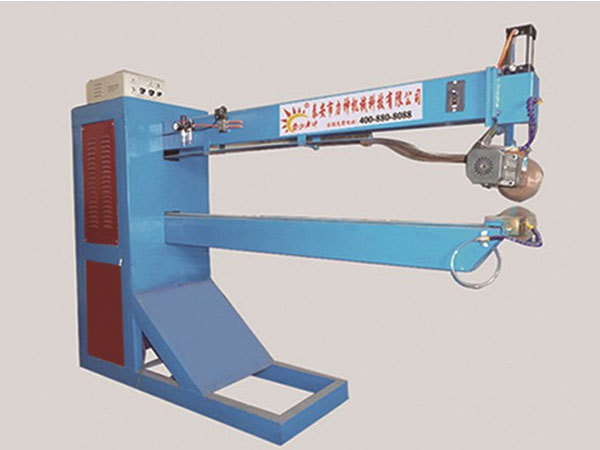

Solar water heaters Double head straight seam welding machine

The straight seam welding machine is mainly used for the straight seam welding of the inner tank of the solar energy project. It can weld all miniature squares and circles within 6MM.Meanwhile, the dual welding head is utilized to individually join the straight and circular seams, rendering it a versatile Resistance Welder that can firmly bond carbon steel, stainless steel, and other high-speed/high-precision plates. With an effective welding length of 1500mm, power output ranging from 50-150KW, and capable of welding thicknesses between 0.1-1.2MM; this machine measures at 2m x 1.1m x 1.8m.

Air Pressure Linear Pulse Seam Welding Machine for Solar Water Heater Inner Tank Welding

The straight seam welding machine is mainly used for the straight seam circular seam welding of the inner tank of the solar water heater, and has the function of spot welding at the same time. It is a multi-functional water tank resistance welding machine.The machine is capable of securely welding carbon steel, stainless steel, galvanized sheet and other plates with high speed and precision, without causing any damage to the stainless steel material. It has a welding length of 1800mm, power ranging from 50-150KW and can weld thicknesses between 0.2-1.2MM. The dimensions of the machine are 2.5m x 0.75m x 1.8m.

Thread head welding machine for solar Manifold

The box wire head welding machine is primarily utilized for the welding of solar energy project wire heads and end covers, delivering stable and high-quality appearance results. With a power range of 50-150KW, it can weld thicknesses ranging from 0.2-1.2M, while its compact dimensions measure at 1.2m x 0.6m x 1.5m.

Solar water heater Nipple Pipe Welding Machine

The wire head argon arc welding machine enables automatic wire head argon arc welding of stainless steel, steel plates, and other materials without deformation or discoloration of the wire head or plate. It can weld thicknesses ranging from 0.2 to 4mm with a length of up to 1 meter. The machine measures 1.5 meters x 0.6 meters x 1.7 meters.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,