Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

The glue dispenser is an automated device that controls, drips, and coats the adhesive and other coatings on the surface of the product. The paint is propelled through the hose by compressed air and then, under program control, dripped or applied according to a preset path. The glue dispenser is primarily used for precise point injection, coating, and dripping of adhesives, paints, and other liquids in the product process to specific positions on each product. This enables the creation of dots, lines, circles or arcs.

Stainless steel solar tank cover mold

The head refers to the element used to close the end of the container to isolate the internal and external media, also known as the end cap.The head of a cylindrical container typically consists of a rotating shell, which can be categorized based on the shape of its surface as either convex, conical, flat or combined. A convex head is one whose outer surface protrudes outwardly and may take the form of hemispherical, elliptical or dish-shaped heads without folds. Some gas cylinders employ a combination bottom head with an inward-facing convexity that not only ensures strength but also meets safety requirements.

The foaming mold is utilized to secure the inner and outer bladders during the combination process of manufacturing the thermal insulation layer for solar water heaters, ensuring a more stable foaming operation with minimal risk of looseness or voids. It plays an essential role in the processing and production of solar water heaters.

Stainless steel solar tank cover mold

The head refers to the element used to close the end of the container to isolate the internal and external media, also known as the end cap.The head of a cylindrical container typically consists of a rotating shell, which can be categorized based on the shape of its surface as either convex, conical, flat or combined. A convex head is one whose outer surface protrudes outwardly and may take the form of hemispherical, elliptical or dish-shaped heads without folds. Some gas cylinders employ a combination bottom head with an inward-facing convexity that not only ensures strength but also meets safety requirements.

Punch Die Tooling Solar Water Heater Machine

The punching dies serve as stamping and forming tools for creating vacuum collector tube holes, upper and lower inlet/outlet openings, and sewage holes in solar water heaters. These dies are designed for reuse and come in various sizes such as 25, 47, 58, etc.

Solar Water Heater Outer Tank Cover for solar water heaters

The solar water heater end cover (water tank head) is mainly stamped from SUS304, 201, galvanized sheet, color steel sheet and other materials. The product boasts a novel design, comprehensive range of models, specifications and types, as well as reliable quality. It can also be tailored to meet the specific needs of customers. The general models are available in sizes ranging from 420mm to 470mm.

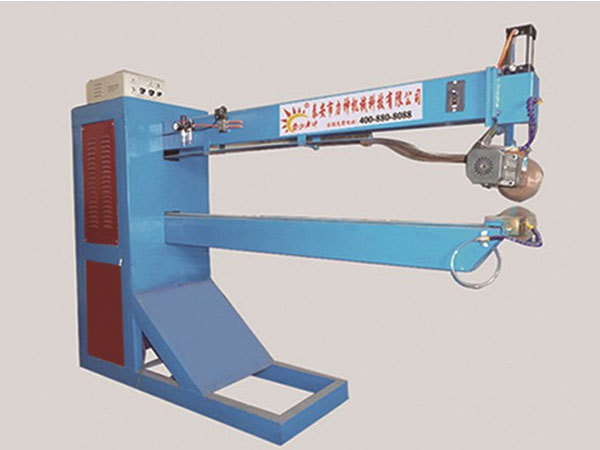

Solar Water Heater Inner Tank Linear Seam Welding Machine

The straight seam welding machine is mainly used for the straight seam circular seam welding of the inner tank of the solar water heater, and has the function of spot welding at the same time. It is a multi-functional water tank resistance welding machine.The machine is capable of securely welding carbon steel, stainless steel, galvanized sheet and other plates with high speed and precision, without causing any damage to the stainless steel material. It has a welding length of 1800mm, power ranging from 50-150KW and can weld thicknesses between 0.2-1.2MM. The dimensions of the machine are 2.5m x 0.75m x 1.8m.

The TIG girth welding machine adopts four-axis CNC welding, and the main engine includes X, Y, Z axis linear motion and R axis rotational motion, which realizes the spatial linear or curvilinear motion of welding and the adjustment of the welding angle between the welding torch and the workpiece. So as to complete the welding work of various special-shaped welds. The equipment consists of a gantry-type welding torch bracket and a welding platform (the welding fixture can be self-made or customized). The machine size is 3.5m x 1.2m x 1.8m.

TIG Straight Seam Welding for Solar Collector Manifold Stainless Water Tank Production Line

The TIG straight seam welding machine is capable of performing butt welding on stainless steel, carbon steel, copper, titanium, aluminum and other metal materials with a high degree of automation and excellent weld quality. It ensures no deformation or intergranular corrosion of the workpiece while allowing for single-sided welding and double-sided forming. This makes it ideal for producing stainless steel products, electric water heaters, solar water heaters and more.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,