Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

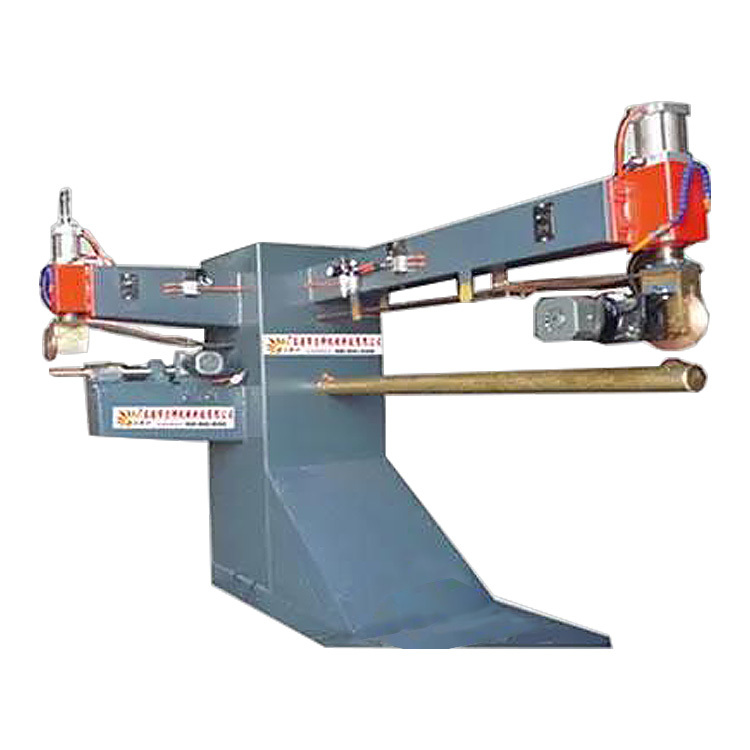

Solar water heaters Double head straight seam welding machine

The straight seam welding machine is mainly used for the straight seam welding of the inner tank of the solar energy project. It can weld all miniature squares and circles within 6MM.Meanwhile, the dual welding head is utilized to individually join the straight and circular seams, rendering it a versatile Resistance Welder that can firmly bond carbon steel, stainless steel, and other high-speed/high-precision plates. With an effective welding length of 1500mm, power output ranging from 50-150KW, and capable of welding thicknesses between 0.1-1.2MM; this machine measures at 2m x 1.1m x 1.8m.

Pneumatic gantry stretching machine

Pneumatic gantry rib-stretching machine is mainly used for pressing ribs in the inner barrel of solar water heaters to enhance the strength of the water tank.The rib size can be adjusted arbitrarily, and the ribs are molded in one go with evenness and wrinkle-free quality. It boasts high-quality ribs with an effective working length of 3000mm, air pressure of 0.5MPa, power of 0.75KW, capable of processing sheet thickness ranging from 0.2-1.2MM while measuring at a machine size of 3.5 meters x 1.1 meters x 1.7 meters.

Manual gantry Grooving Machine

The manual gantry rib-stretching machine is mainly used for pressing the ribs in the inner barrel of the solar water heater to enhance the strength of the water tank.The pressing ribs can be adjusted to any size as needed. With an effective working length of 1500mm and a power output of 0.75KW, this machine is capable of processing plates with a thickness range of 0.2-0.6MM. Its dimensions are 2.1 meters in length, 1.1 meters in width, and 1.7 meters in height.

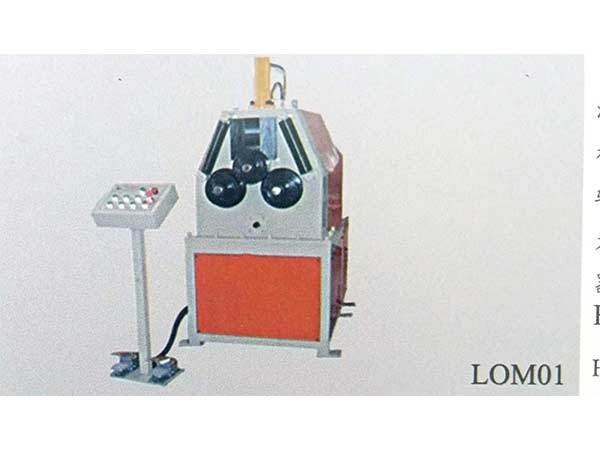

Hydraulic pipe and section bending machines

The hydraulic rolling machine is operated by a hydraulic system that controls the lifting of the upper roller. It comes with adjustable support rollers on both sides and standard configuration of rolling reels for flat iron and angle iron (other reels can be customized according to customer requirements). Independent movable electrical appliances control the forward and reverse rotation of the two lower power rollers, which have pre-bending function to save material. The machine boasts stable quality and high cost performance, with a size of 0.8m x 1.1m x 1.7m.

Mechanical Pipe Angle Channel Bending Machine

The channel steel rounding machine utilizes the molds on its three rollers to bend various profiles into circular, isolated, and spiral shapes with a specific curvature. Its combined mold design allows for versatility in profile application through simple changes and combinations. This high-quality and efficient rolling device is ideal for producing rings and flanges. With a power output of 7.5KW, it can accommodate any circle size or material thickness while maintaining compact dimensions of 2.5 meters x 1.1 meters x 1.5.

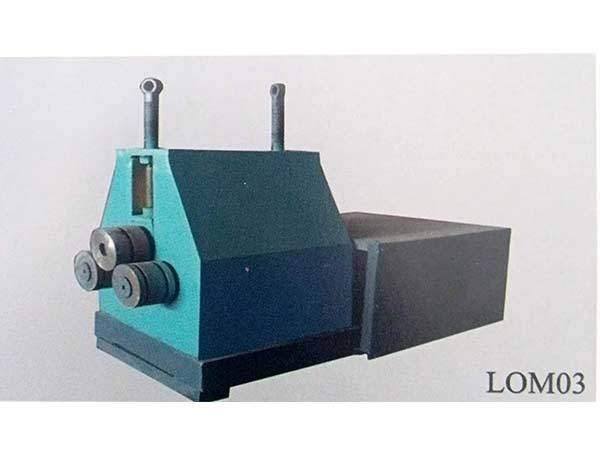

Steel pipe tube rolling electric pipe rolling machine

The angle iron rolling machine is capable of replacing rolls to accommodate various needs, enabling the rolling of angle iron, flat iron, round pipe, channel steel, square pass and more. The three rolls can adjust the roll gap during operation for stable forming and high efficiency. Different rolling dies can be installed according to customer material requirements with a power output of 1.5KW and dimensions measuring 0.8m x 1.1m x 1.7m.

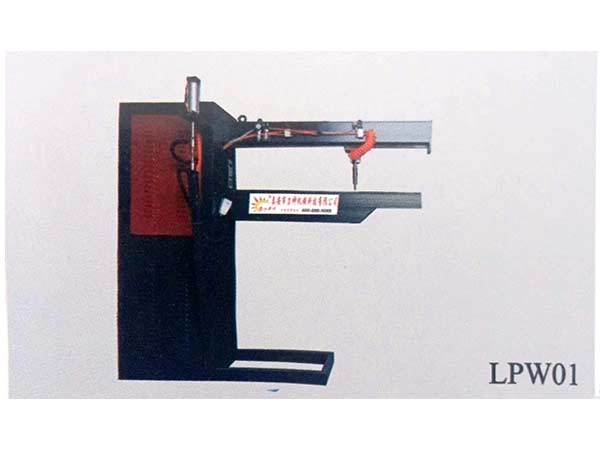

Double head spot welding machine for solar water heater

The double-headed spot welding machine is a foot-operated single-head spot welding equipment, which is primarily utilized for the purpose of spot welding stainless steel water tower barrels and end covers. With advanced technology, it ensures even stress distribution at the weld points and firm bonding. It has a power output ranging from 25-50KW and can weld thicknesses between 0.2-1.0MM, while its dimensions are 1.2m x 0.6m x 1.5m.

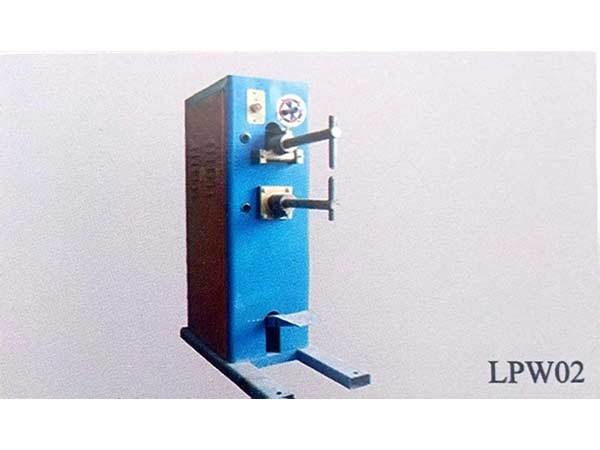

Single head spot welding machine for solar water heater

The foot-operated single-head spot welding machine is specifically designed for the purpose of welding the barrel body and end cover of stainless steel water towers. With a power range of 25-50KW, it can weld thicknesses ranging from 0.2-1.0MM, while its compact size measures at 1.2m x 0.6m x 1.5m.

The hydraulic shearing machine features an integral welded frame structure that has undergone vibration failure treatment, as well as hydraulic transmission and nitrogen return systems. It is equipped with a fence-type electrical interlocking safety protection device, cutting edge gap adjustment indicators for quick and easy adjustments, a digital display for the back gauge size and number of cuts made, and a light alignment device to facilitate marking and cutting.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,