Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

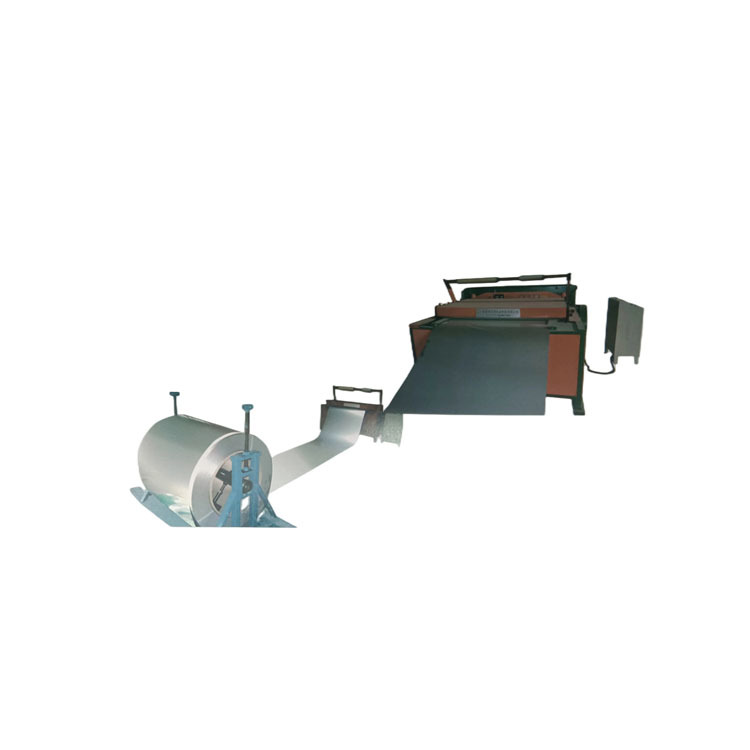

Solar Water Heater Production Line - Hydraulic Metal Plate Shearing Machine

The mechanical shearing machine features a compact and simplistic structure, incorporating a clutch mechanism comprised of resistance keys and open gear transmission. It also utilizes advanced electrical components to ensure low operational noise, easy maintenance, aesthetically pleasing design, safety and reliability. This machine is primarily designed for cutting various types of plates with an effective working length of 3000mm, power output of 4KW and capable of shearing plate thicknesses ranging from 0.1-12MM. Machine dimensions are measured at 3m x.

The pneumatic shearing machine boasts a simplistic structure, effortless operation, and eliminates the need for foot pedals or motor drives. It saves time and effort while maintaining low processing costs. This machine is primarily utilized for sheet shearing in solar water heater and water tower facilities with an effective working length of up to 3000mm and capable of cutting through plates ranging from 0.1-1.2M thick. Its dimensions are 3.5m x 0.8m x 1.3m.

The CNC shearing machine consists of a CNC control cabinet, an electric shearing machine, a leveling machine, a material support frame, and a laminating part. Its operation is simple with one-time setting for automatic shearing which saves time and effort. It finds wide application in the processing and production of solar inner and outer bladders, brackets, barrel supports etc., mainly used for cutting various types of plates without limitation on their length or width.

The pedal shearing machine boasts a simplistic structure, user-friendly operation, non-reliance on power supply and negligible processing costs. It is primarily utilized for the thin plate shearing of solar water heaters and water tower facilities. With an effective working length of up to 3000mm and capable of cutting through plates with thicknesses ranging from 0.1-1.2M, this machine measures at 3.5m x 1.3m x 1.5m in size.

Hydraulic Pressure Machine Forming High Precision High Level

The four-column press is equipped with three speeds for no-load fast, slow die and workpiece deep drawing. It boasts high work efficiency, low energy consumption, convenient operation, stable performance and other advantages. It finds extensive applications in metal pressing, forming, bending as well as flanging correction and other processes. The size of the worktable and the tonnage of hydraulic cylinder can be customized according to customer requirements.

The head spinning machine is utilized for flanging and spinning various heads, including stainless steel and carbon steel special-shaped heads, straight cylinders, conical heads, flat-bottomed heads, as well as spinning and folding. It features stable lifting, effortless operation, mobile control customizable to customer needs. The machine can be tailored to specific requirements with ease of installation and maintenance due to its compact structure that ensures reliability.

Seaming Machine for Solar Water Heater Inner Tank Production

Automatic seaming machine is mainly used for straight seam undercut. It can independently move undercut and press, with high speed, uniform press without wrinkles, large length, suitable for long water tank processing, high efficiency and labor saving. The effective working length of the machine can reach up to 3000mm, with a power output of 1.5KW and a plate thickness range of 0.2-1.2MM. The overall dimensions of the machine are 3.5m x 1.3m x 1.8m.

Semi-automatic Seaming Machine solar water heater production line

Semi-automatic seaming machine is mainly used for straight seam undercut. It can independently move undercut and press, with high speed, uniform press without wrinkles, large length, suitable for long water tank processing, high efficiency and labor saving.The effective working length of the machine can reach up to 3000mm, with a power output of 1.5KW and a plate thickness range of 0.2-1.2MM. The overall dimensions of the machine are 3.5m x 1.3m x 1.8m.

Ordinary Seaming Solar Water Heater Machinery

The ordinary seaming machine is primarily utilized for processing water tanks and buckets that have been buckled and tenoned. It boasts an effective working length of up to 3000mm, a power output of 0.75KW, the ability to process sheet thicknesses ranging from 0.2-1.2MM, and measures at a size of 3.5 meters *1.8meters *0.9meters.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,