Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

Single head Necking/Shrinking Machine for Solar buffer water tank production line

The single-head shrinking machine is a novel equipment designed for taper shrinking of solar outer casings. It employs a single-head gear engagement mechanism, resulting in evenly ribbed and high-strength edges with remarkable speed. This machine can process barrels of different diameters on one platform while ensuring muscle constriction. With 0.75KW power output, it processes sheets ranging from 0.2-1.2MM thickness and measures 3.5 meters x 0.8 meters x 1.5 meters.

The double-head shrinking machine is a specialized equipment designed for tapering and compressing the outer bladder of solar panels. It can extrude outer bladders made from different materials and with varying diameters, and can operate using one or two heads simultaneously, with manual or pneumatic adjustments available. This high-efficiency machine boasts advanced technology and wide-ranging applications, featuring an effective working length of 3000mm, a power output of 0.75KW, and capable of processing plate thicknesses ranging from 0.2-1.2MM.

Hydraulic Necking/Shrinking Machine Buffer tank production line

The hydraulic compression machine is utilized for the reduction of pressure vessels and solar water heaters. The end cap size requires no mold replacement, making shrinking a simple and convenient process with fast benefits. Automatic positioning and alignment, one-time spinning forming, high flaring precision, and an advanced gas and liquid control system ensure the reliability of the entire machine.

Automatic Seaming Machine solar water heater production line

Automatic seaming machine is mainly used for straight seam undercut. It can independently move undercut and press, with high speed, uniform press without wrinkles, large length, suitable for long water tank processing, high efficiency and labor saving. The effective working length is up to 3000mm, the power is 1.5KW, the thickness of the plate can be 0.2-1.2MM, and the machine size is 3.5m x 1.3m x 1.8m.

Solar Water Heater Tank Production Line--Manual Seaming Machine

The ordinary seaming machine is mainly used for processing water tanks and buckets that have been buckled and tenoned for digging and compacting. The effective working length is up to 3000mm, the power is 0.75KW, the thickness of the processed sheet is 0.2-1.2MM, and the machine size is 3.5m*1.8m*1.5m

Ordinary Seaming Solar Water Heater Machinery

The ordinary seaming machine is primarily utilized for processing water tanks and buckets that have been buckled and tenoned. It boasts an effective working length of up to 3000mm, a power output of 0.75KW, the ability to process sheet thicknesses ranging from 0.2-1.2MM, and measures at a size of 3.5 meters *1.8meters *0.9meters.

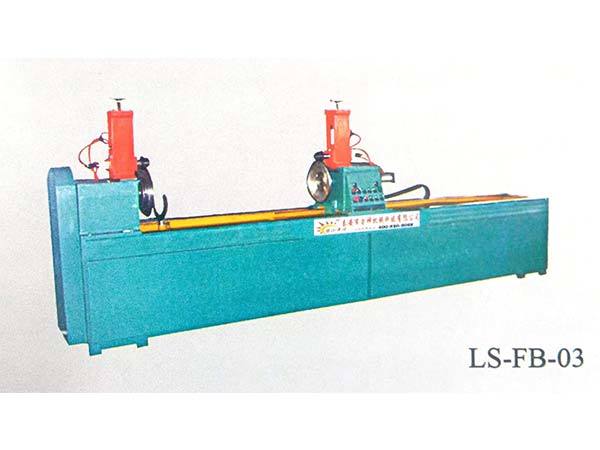

Semi-automatic Seaming Machine solar water heater production line

Semi-automatic seaming machine is mainly used for straight seam undercut. It can independently move undercut and press, with high speed, uniform press without wrinkles, large length, suitable for long water tank processing, high efficiency and labor saving.The effective working length of the machine can reach up to 3000mm, with a power output of 1.5KW and a plate thickness range of 0.2-1.2MM. The overall dimensions of the machine are 3.5m x 1.3m x 1.8m.

Ordinary welding-free four-wheel sealing machine

The ordinary welding-free sealing machine is mainly used for welding-free sealing of the inner tank head of the solar water heater. The machine boasts high production efficiency, user-friendly operation, corrosion resistance, aesthetically pleasing design, advanced automation and minimal workpiece deformation. It has a working length of 3000mm, air pressure of 0.5MPa and power output of 1.5KW; it can process sheet thicknesses ranging from 0.2-0.6MM with ease. The machine measures at 3.5m x 1.lm x l.Sm.

Bending and Locking Machine for Outer Tank

The welding-free sealing machine is mainly used for welding-free sealing of the inner tank head of the solar water heater. The product is roll-formed, boasting high production efficiency and simple operation. It features a corrosion-resistant finish, an aesthetically pleasing shape, high automation levels, and no workpiece deformation. With a working length of 3000mm, air pressure of 0.5MPa, power output of 1.5KW and the ability to process sheet thicknesses ranging from 0.2-0.6MM; this machine measures at 3.5m x 1.lm x l.Sm.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,