Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

Grooving Machine for Solar Geyser Inner Tank Processing

The inner tank reinforcement machine is mainly used for the reinforcement of the inner barrel of the solar water heater to enhance the strength of the water tank.The operational length measures 2000mm, while the air pressure stands at 0.5MPa. The thickness of the processed sheet ranges from 0.2-1.2MM, and the machine dimensions are 2.5m x 0.8m x 1.7m.

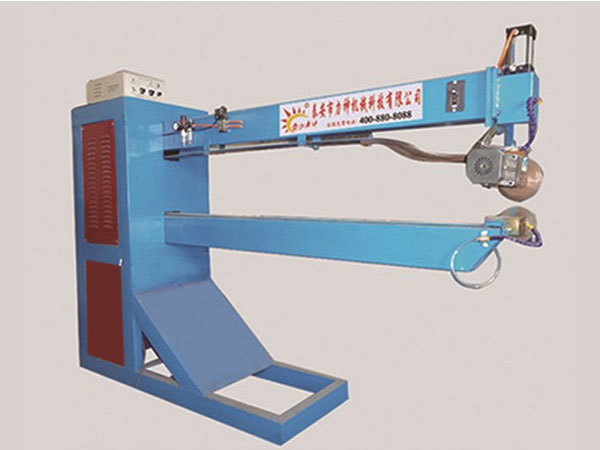

Solar Water Heater Inner Tank Linear Seam Welding Machine

The straight seam welding machine is mainly used for the straight seam circular seam welding of the inner tank of the solar water heater, and has the function of spot welding at the same time. It is a multi-functional water tank resistance welding machine.The machine is capable of securely welding carbon steel, stainless steel, galvanized sheet and other plates with high speed and precision, without causing any damage to the stainless steel material. It has a welding length of 1800mm, power ranging from 50-150KW and can weld thicknesses between 0.2-1.2MM. The dimensions of the machine are 2.5m x 0.75m x 1.8m.

TIG Straight Seam Welding for Solar buffer water tank production line

The TIG straight seam welding machine is capable of performing butt welding on stainless steel, carbon steel, copper, titanium, aluminum and other metal materials with a high degree of automation and excellent weld quality. It ensures no deformation or intergranular corrosion of the workpiece while allowing for single-sided welding and double-sided forming. This makes it ideal for producing stainless steel products, electric water heaters, solar water heaters and more.

TIG Circumferential Welding Machinery for Solar buffer water tank production line

The TIG girth welding machine utilizes a four-axis CNC welding system, with the main engine featuring linear motion in X, Y, and Z axes as well as rotational motion in R axis. This enables both linear and curvilinear spatial movement of the welding process while allowing for adjustment of the angle between the torch and workpiece to complete various special-shaped welds. The equipment comprises a gantry-type welding torch bracket and a customizable welding platform (with self-made or custom fixtures).

The automatic hemming machine is primarily utilized for straight seam hemming. The board's width can be independently adjusted, and its length is unrestricted. It can fold on one or both sides simultaneously, accommodating plates and strips alike. Additionally, it can produce C-shaped folds on one side and J-shaped folds on the other concurrently, resulting in high efficiency, labor savings, and aesthetically pleasing edges. Its power output is unchanged.

Manual hemming machines are primarily utilized for straight seam hemming and serve as specialized equipment for solar water heaters, various thin-plate ventilation pipes, and snap-button forming. With an effective working length of up to 2800mm and a plate thickness capacity of 0.6mm, the machine measures at 2.85m x 0.7m x 1.3m in size.

Electric tenoning machine is primarily utilized for straight seam hemming. It features electric quick operation, unlimited length, adjustable hemming width, beautiful shape, low cost and easy mobility. The tenon width measures 6-8mm with a power of 1.5KW and can process plate thicknesses ranging from 0.2-1.2M. The machine size measures at 1.2m x 0.8m x 1.4m.

Hydraulic Tenon Bending Solar Water Heater Machinery

This machine is a general-purpose thin-plate folding machine. It can be bent into various cross-sectional shapes after one or more folding steps and at the same time changing the cutter as needed. Widely used in the manufacture of automobiles, ships, electrical appliances, kitchen utensils and air conditioning and ventilation equipment. The body is all welded with high-quality steel plates. Compact structure, high strength, sturdy and durable, elegant appearance, safe and reliable, simple operation; convenient adjustment and maintenance.

Electric Stainless Steel Metal Sheet Laminating Machine solar water heater tank production

The electric laminating machine is utilized for applying a protective film onto the surface of color-coated and galvanized sheets, as well as other thin sheets, to prevent oxidation caused by acid and alkali exposure, rusting, and enhance their corrosion resistance and wear resistance properties. It has an effective working length of 1300mm, power rating of 0.75XW, with dimensions measuring at 1.8m x 0.8m x 1.4m.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,