Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

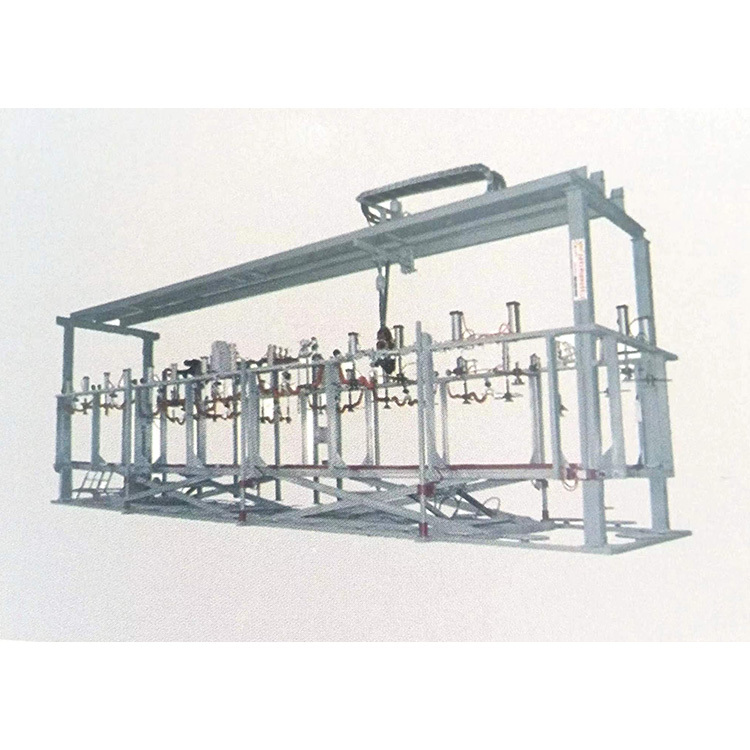

Solar Water Heater Hydraulic Foaming Machine

The SBP technology implemented in the hydraulic foaming machine ensures stable raw material flow pressure, while its powerful power resolves gun blockage issues. Its user-friendly operation platform simplifies overall machine operation, making it easily mastered by anyone. With a 7.5KW power output and dimensions of 1m x 1m x 1.2m, this machine is an excellent choice for foam production.

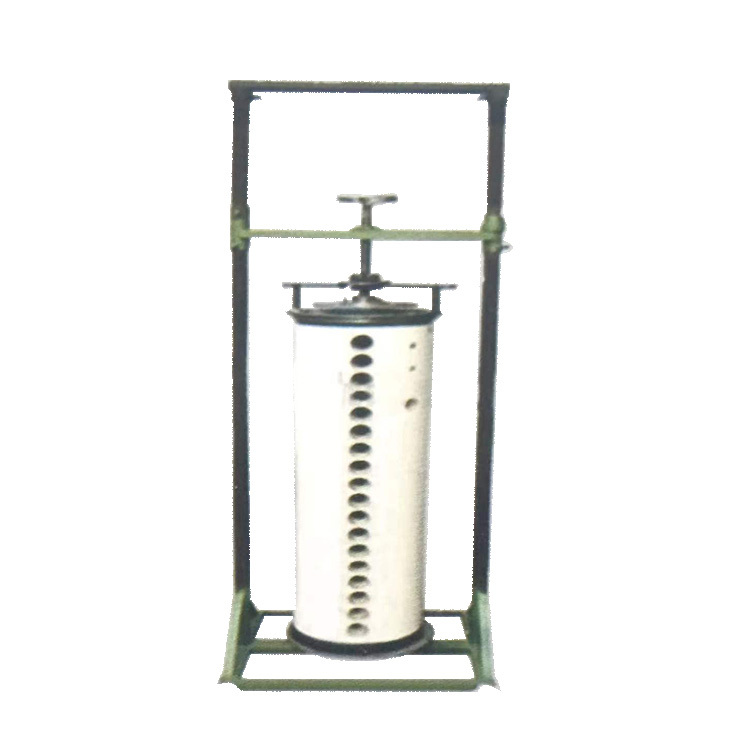

Single station Foaming Machine Solar Water Heater Foaming Line

The independent foaming frame securely fixes the inner and outer barrels, preventing eccentricity and shifting. This allows for one-time polyurethane foam injection, achieving overall foaming effects. Multiple independent foaming racks can be used in series to enable multi-station simultaneous foaming and improve efficiency

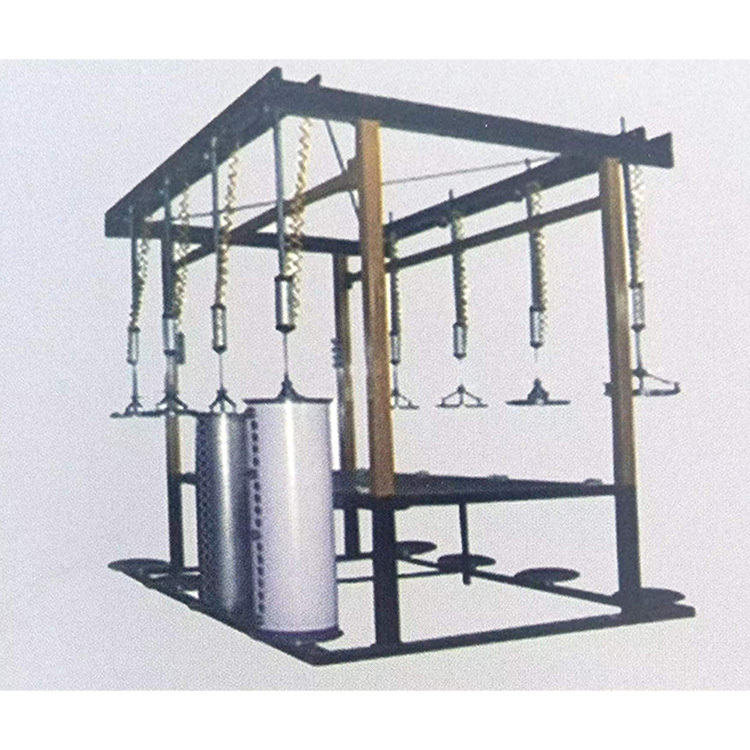

Multi-station Foaming Machine Solar Water Heater Foaming Line

The multi-station foaming rack is a versatile foam production line that can be operated independently or in combination, offering high flexibility and efficiency at low cost. It is an essential tool for producing solar water heaters with superior insulation properties.

The foaming mold is utilized to secure the inner and outer bladders during the combination process of manufacturing the thermal insulation layer for solar water heaters, ensuring a more stable foaming operation with minimal risk of looseness or voids. It plays an essential role in the processing and production of solar water heaters.

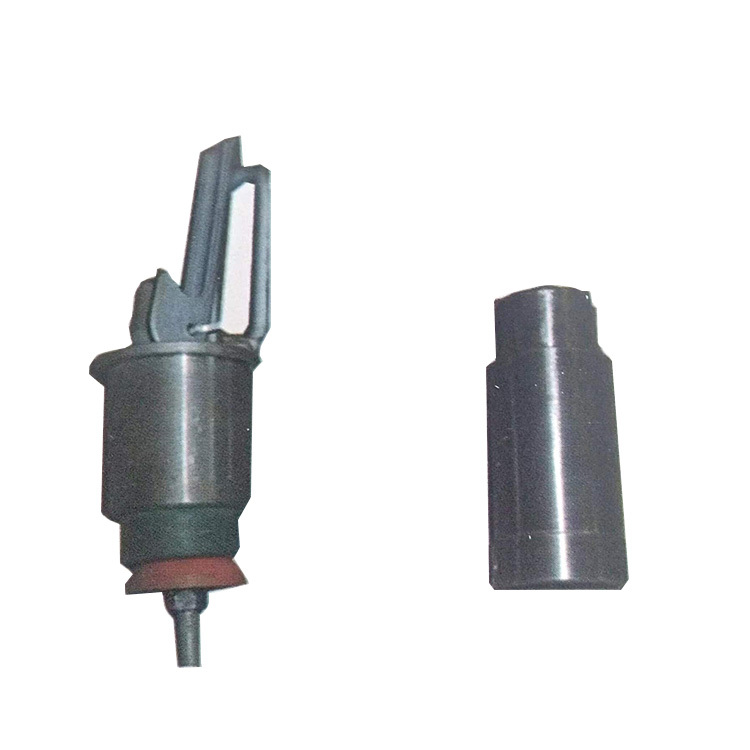

The foam plug is utilized to seal the mouth of the vacuum heat collector during the production of insulation layer for female Yang energy water heater, ensuring air tightness and integrity of foam, thereby enhancing insulation effect. It can be classified into ordinary foam plugs and positioning foam plugs.

Multi-station Foaming Machine Solar Water Heater Foaming Line

The multi-station foaming rack is a versatile foam production line that can be operated independently or in combination, offering high flexibility and efficiency at low cost. It is an essential tool for producing solar water heaters with superior insulation properties.

Small Deep Drawing Machine for Electric Water Heater Inner End Cover Production Line

The small press is mainly composed of a frame, four uprights, an oil cylinder, a hydraulic station, a fuel tank and other parts. The machine is primarily utilized for the production and processing of inner and outer bladder heads as well as barrel supports in solar energy applications. It boasts a compact size, low energy consumption, ease of operation, and high safety factor. With a tonnage range of 10-100 tons, power output of 7.5K, ability to process sheet thicknesses ranging from 0.2-1.2M, and dimensions measuring at 2m x 1.1m x 1.7m.

Stretching Machine for Electric Water Heater Inner End Cover Production Line

The calibration hydraulic press is primarily utilized for the precise calibration and press-fitting of shafts and sleeves, as well as other similar technological applications. The machine's structure features a single-column upright design that ensures reliability.

Electric Water Heater Inner End Cap Deep Drawing Machine

The four-column press is equipped with three speeds for no-load fast, slow die and workpiece deep drawing. It boasts high work efficiency, low energy consumption, convenient operation, stable performance and other advantages. It finds extensive applications in metal pressing, forming, bending as well as flanging correction and other processes. The size of the worktable and the tonnage of hydraulic cylinder can be customized according to customer requirements.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,