Email : sales03@fujad.com Tel :8617852488518

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

SOLAR EQUIPMENT

Upper and lower double cylinder for Electric Water Heater Inner End Cap

The upper and lower double-cylinder stretching press is primarily designed for cold and hot pressing of various container heads. It can also be utilized for a range of thick and thin steel plates, including drum pressing, hemming, leveling, among other processes. The hydraulic control system features an integrated cartridge valve that ensures reliable action with minimal hydraulic shock while reducing connection pipeline and leakage points. Additionally, the button centralized control allows for easy selection.

Four-column three-beam double-cylinder Deep Drawing Press Machine

The three-beam and four-column structure is both economical and practical, featuring an integrated hydraulic control system with cartridge valves to minimize leakage points. This ensures reliable operation and a long service life. It supports two forming processes - fixed pressure and fixed stroke - that can be adjusted within the specified range via centralized button controls for manual, semi-automatic or automatic operations.

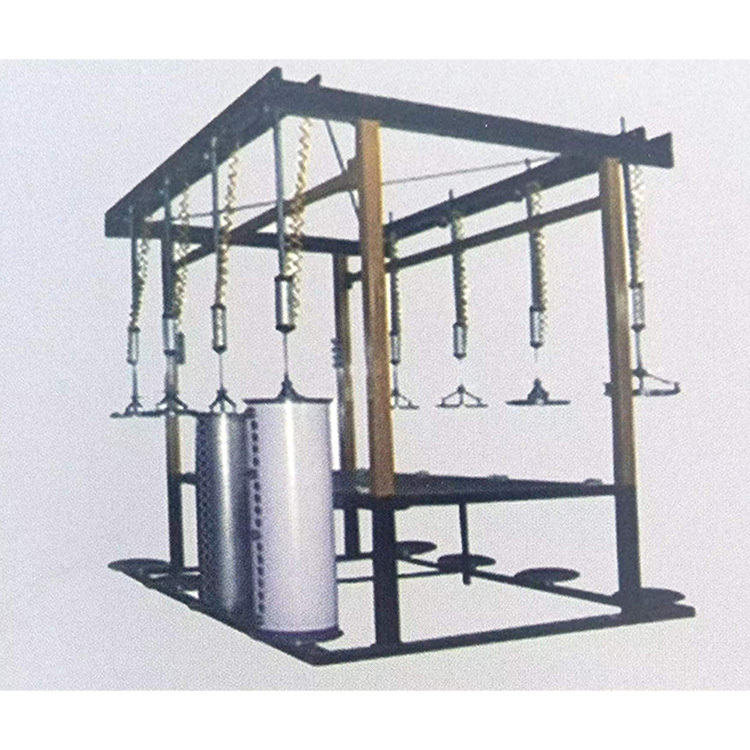

Multi-station Foaming Machine Solar Water Heater Foaming Line

The multi-station foaming rack is a versatile foam production line that can be operated independently or in combination, offering high flexibility and efficiency at low cost. It is an essential tool for producing solar water heaters with superior insulation properties.

Multi-station Foaming Machine Solar Water Heater Foaming Line

The multi-station foaming rack is a versatile foam production line that can be operated independently or in combination, offering high flexibility and efficiency at low cost. It is an essential tool for producing solar water heaters with superior insulation properties.

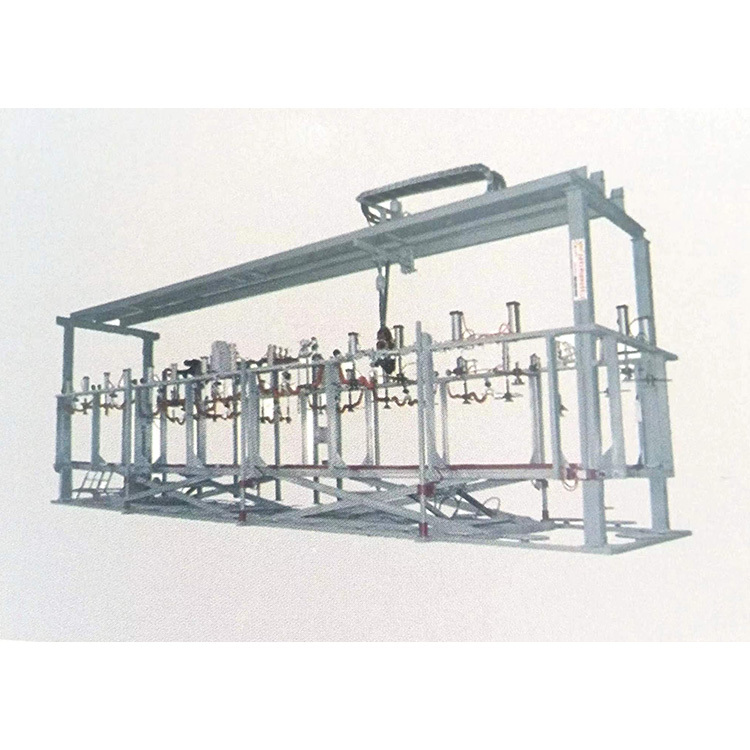

Solar Water Heater U Type Foaming Line

The U-shaped foam production line is a solar foaming production line that circulates on a ground rail with 30 to 85 stations (the exact number of stations can be determined). It can operate continuously or step by step, and boasts a compact structure, simple operation, stable transmission, and high efficiency. This feature-rich equipment finds wide application in the mass production of solar panels.

Solar Water Heater Turntable Foaming Machines

The turntable foaming line is an 8-station turntable foam production line that boasts a small footprint, high flexibility, convenient operation and excellent foaming performance. It is an indispensable piece of equipment in the manufacturing industry for solar water heaters and electric water heaters.

Ordinary non-welding four-wheel sealing machine for Automatic Solar Water Heater Inner Tank Ends

The machine boasts high production efficiency, user-friendly operation, corrosion resistance, aesthetically pleasing design, advanced automation and minimal workpiece deformation. It has a working length of 3000mm, air pressure of 0.5MPa and power output of 1.5KW; it can process sheet thicknesses ranging from 0.2-0.6MM with ease. The machine measures at 3.5m x 1.lm x l.Sm.

Automatic Circular Sheet Metal Cutting Machine for Solar energy inner tank production line

The automatic circular shearing machine boasts a well-structured and innovatively designed system that enables seamless cutting of the entire sheet without any burrs, while ensuring fast speed, high-quality output, and maximum material utilization rate. It can also process end caps with diameters ranging from Ф250mm to 600mm. With a power rating of 1.5KW, it can cut round plates with thicknesses between 0.1-1.2MM, and has dimensions of 0.8m x 1m x 1.4m.

Circular Sheet Metal Cutting Machine for Solar Water Heater Tank Production Line

The gantry circular shearing machine is capable of cutting both the inner and outer circles of a plate with its advanced pressing technology, eliminating the need for punching holes prior to cutting. The resulting cut disc boasts a uniform shape and smooth curve, making it ideal for producing equipment accessories such as filters, pressure vessels, and stoves. With its wide range of applications and high production efficiency, this machine can automatically adjust the size of the cut circle without limitations on thickness.

CONTACT US

Tel400880

Mobile :+86-17300933771

Email : sales01@fujad.com

Whatsapp:+86-17300933771

Address : No. 4 Workshop, Zone A,

Press and Publication Town, High tech

Zone, Tai'an, Shandong

Address : No. 4 Workshop,